rotolo industriale di grande formato per rotolare Konica 512i stampante solvente WER-K3204I

specificazioni

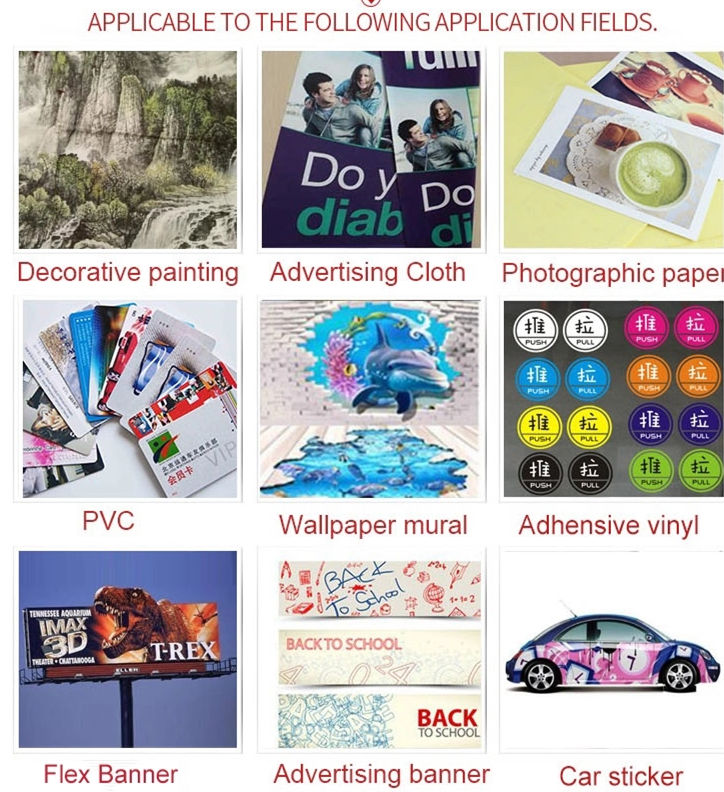

Usage:Paper Printer, Vinyl sticker,Flex banner

Plate Type:Roll to roll printer

Tipo: stampante a getto d'inchiostro

Grado automatico: automatico

Tensione: 220V

Dimensions(L*W*H):4700mm*1100mm*1500mm

Weight:650kg

Garanzia: 1 anno

Print Dimension:3.2m

Ink Type:Solvent Ink

Drying System:Infrared drying

Cleaning System:Automatic

RIP Software:Ultraprint, Photoprint

Data Interface:3.0

Auto Media Feeding System:Equipped

Media Type:Paper/flex banner/vinyl

Heating System:Front heating and after heating

Media Transmission:Roll to roll

Keywords:konica 512i solvent printer

Perché sceglierci

1. We are professional manfacture located in shanghai, WER is our own brand. We believe that

we can give you professional suggestion with more than 20 years experience. Welcome to

visit our factory;

2. Excellent after sale service, good quality, fast delivery, which is worthy of your trust;

3. The platform is equipped with a direct current turbofan, and strong wind can adjust the wind

force;

4. The feeding system adopts the synchronous transmission gear, stable transmission;

5. The material roller is fixed on both sides of the roller to prevent deviation of material;

| Modello | WER-K3204I | |

| Type of Printheads | Piezo-electric printhead , KM512i(30PL) | |

| Quantity of Printheads | 8 Heads | |

| Width of Media | 3.2m | |

|

Printing Speeds

| Alta velocità | 360×360dpi: 270m^2/h 2pass |

| Middle Speed | 360×540dpi: 180m^2/h 3pass | |

| Low Speed | 360×720dpi: 130m^2/h 4pass | |

| Tipo di inchiostro | Less solvent and solvent base CMYK | |

| Printing Media

| Papers, Advertising Banner, PVC, Advertising Cloth, Adhesive Vinyl,Mesh, and soft media below 5mm in height. | |

| Adjustable Height of Carriage | 0.5mm | |

| Machine Size(L*W*H) | 4700mm*1100mm*1500mm | |

| Packing Size (L*W*H) | 4980mm*740mm*1130mm | |

| Net Weight/Gross Weight | 650kg/750kg | |

FAQ

1. A single nozzles can not be made out of ink?

Replacing the nozzle, replacing the sprinkler data line or the nozzle switch board, inserting the data line of the nozzle, repairing the ink supply system, and replacing the main plate

2, all the spray head is not out of ink?

Repair the power, replace the head card, replace the main board, reinstall or replace the decoder, reinsert or replace the fiber line

3. Broken line?

Improve the temperature of the environment, adjust the voltage of the nozzle, clean the nozzle with the cleaning liquid and replace the ink

4. Unable to discharge material?

Replacement of photoelectric switch, replacement of discharge motor or rewiring

5. Middle wrinkle when walking?

Re feed, adjust the parallelism of the feed wheel and the feed wheel shaft, and adjust the pressure of the press wheel

6. No moving head or software part function can't be used?

Replacement of main board, rewiring, reconnection or replacement of drive, replacement of motor or rewiring

7. Stop spray?

Replace the decoder and grating, adjust the position of the decoder to the middle of the decoding bar, replace the motor, or change the material to the small volume

8. Inability to provide ink?

Replace the cartridge inductor, replace or reconnect, replace the main board, replace the ink pump, and replace the filter

9. For ink supply?

Replacement of the main board and rewiring

10. The print test bar and the diagram are not normal?

Change the grating or decoder, reconnect the fiber line, replace the driver, and replace the main board